ATTACHMENT METHODS

Cover boards, like all components of a roof system, need to be compatible with the insulation, roof membrane and attachment methods. Attachment methods include hot asphalt, cold adhesive, bead polyurethane foam and spray polyurethane foam, as well as mechanical attachment.

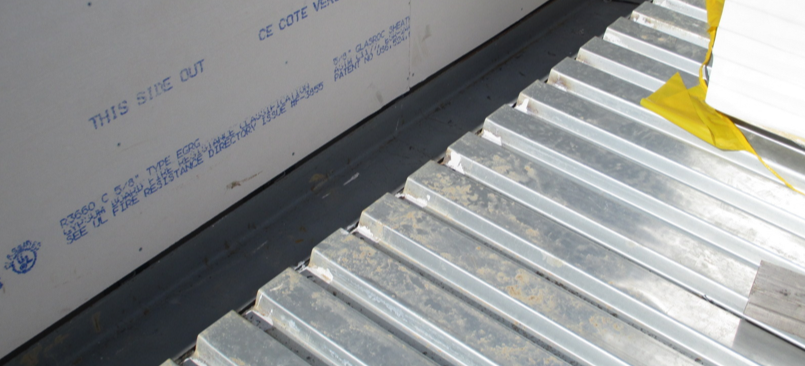

Glass-mat-faced gypsum boards can be mechanically fastened and set in various adhesives. In the photo, the cover board is mechanically attached and set in bead polyurethane foam and hot asphalt. PHOTO: Hutchinson Design Group

GOOD PRACTICE

Cover boards are an important and integral part of the roof system and when properly specified and installed will enhance the roof system’s ability to achieve a greater service life and reach sustainability. Cover boards’ use can now be considered good roofing practice.

Learn More

Additional Information can be found in the NRCA Waterproofing Manual. Read articles by Dr. James Hoff, “The Sustainable Roof Cover Board”, Roofing Contractor, April 2015, and Jason Wilen, “Covering Your Options”, Professional Roofing, May 2014. Also, view various cover-board manufacturers’ product data sheets.

MORE FROM HUTCH

“Roofs Are Systems”, January/February 2014, page 52

“Roof Decks”, March/April 2014, page 54

“Substrate Boards”, July/August 2014, page 52

“Vapor Retarders”, September/October 2014, page 52

“Insulation”, November/December 2014, page 50

“Wind-damaged Roof Systems”, January/February 2015, page 60

Efficiency is something that is really important to me. A lot of people take it for granted until it’s gone or live somewhere with poor insulation. Getting the right layer can literally save you a ton of money on your heating bill when the time comes. Thanks for bringing this up and great tips!