Sealants represent a relatively small cost in metal construction, but the price to pay if the right sealant and proper application methods aren’t used could be substantial. Sealants used in metal construction are not easily repaired or replaced without potential damage to panels or other parts. When the wrong sealant is used for a metal roof, the overall roof itself could fail. To avoid sealant failure and achieve a long service life on any metal building’s roof or wall component, professionals need a firm understanding of the sealant options available and the application guidelines to follow.

The Metal Construction Association (MCA) has released an important new Technical Bulletin, “Best Practices: Metal Building Sealant Types and Application Guidelines.” The document details the benefits, features, and limitations of the most commonly used sealants in metal construction: butyl, polyurethane, and silicone, as well as the most effective procedures for utilization.

Sealant Failure and the Consequences

When sealants fail, metal roof panels can often be damaged severely enough in order to require replacement. Incorrect sealant application, inadequate surface preparation, and early or excessive joint movement can also result in a cracked sealant. That can be expensive and labor intensive.

Sealant Options

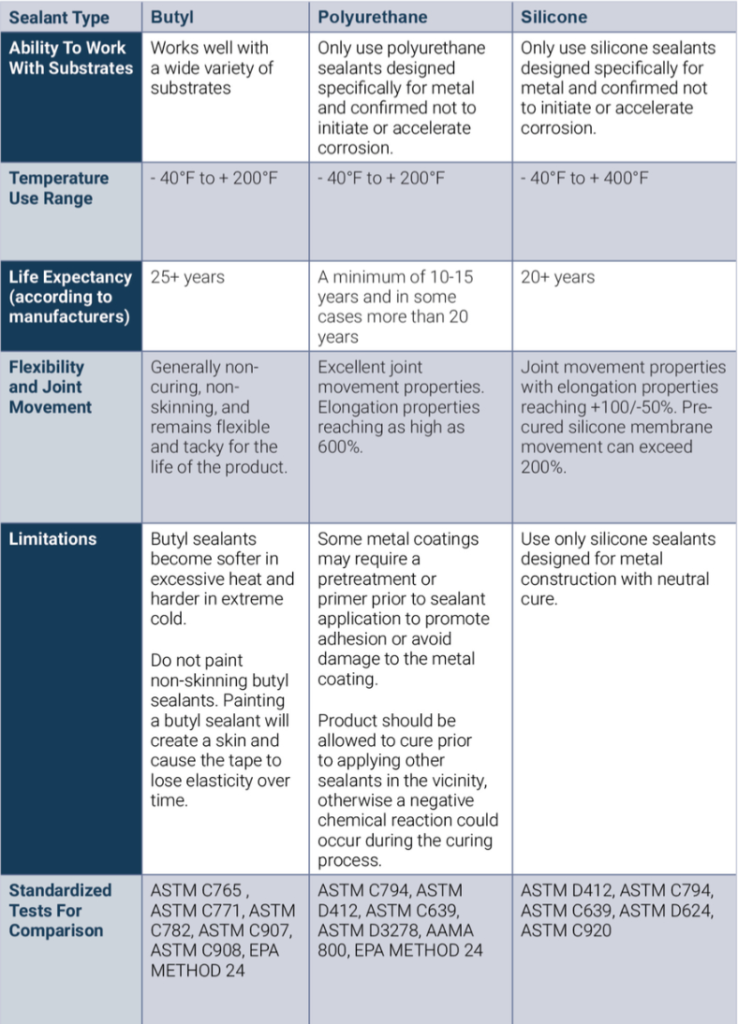

Butyl, polyurethane, and silicone are three of the most commonly used sealants for metal roofing. When properly applied, they can all provide long life and should accommodate normal movement through the design of the joint itself.

The chart in Figure 1 compares the products’ characteristics and limitations.

Best Practices

Just as important as using the right sealant is applying the sealant properly. Best practices include:

· Use only what is needed. Although it may appear harmless to add more sealant than required, this can cause issues of separation and buckling of the connection and expansion joints long after the sealant has been installed. Follow manufacturer instructions carefully.

· Set it on site. Sealants should be applied at the building construction site, at the moment required to continue construction. Doing so ahead of time can lead to deformed, damaged, or contaminated sealants. (Note: Some manufacturers design and engineer sealants to be pre-applied to substrates at the time of production.)

· Dry + Clean = Success. A dry surface is required for sealants to adhere properly. Inspect surfaces for liquid or frozen moisture before applying the sealant. Even a small amount of moisture could compromise the performance of the sealant over the life of the material joint or lead to mold and mildew that may further compromise any sealant over time. Likewise, ensuring the surface is clean and free of any residue or dust or debris is also important.

· Set your standards. Standardized test results are preferable to manufacturer data to determine the fitness of a particular sealant type. ASTM, UL, and AAMA are internationally recognized standards that generally require third party independent laboratory testing. Frequently, there are regional and local test standards that must be completed to show the sealant material meets the project performance requirements.

Sealants are an excellent example of the old saying, “Everything counts in large amounts.” When sealant fails, roofing can become damaged to the point of requiring an expensive replacement.

The full technical bulletin is available at www.metalconstruction.org.

About the author: Miguel Pena is the Vice President of GSSI Sealants, Inc., a manufacturer of premiere butyl rubber sealants for the metal building industry. GSSI Sealants has been a member of the Metal Construction Association for more than a decade.

Be the first to comment on "The Best Sealants For Metal Buildings"