MODIFIED BITUMEN

Unlike built-up roofing products (BUR), modified bitumen offers “built-in” waterproofing (versus field applied). Initially, it was offered to address some of the in-field construction concerns associated with BUR. Modified bitumen has been a major roof cover for more than 40 years (see photo 6).

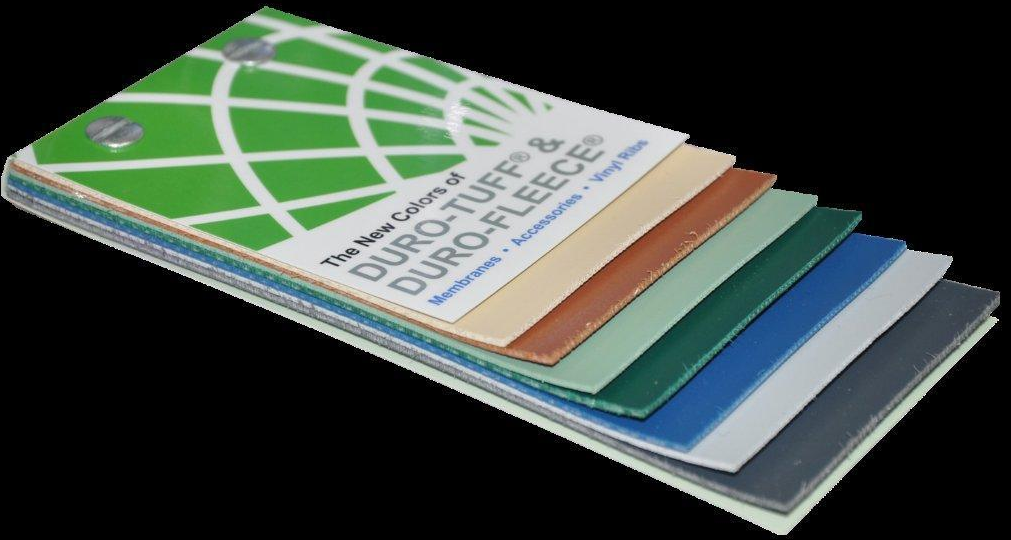

PHOTO 5: This fully adhered PVC with a custom color was selected to mimic the terne-coated steel roof it replaced.

The membrane (plies) can be manufactured with fiberglass or polyester reinforcing or both, and the cap or top sheet can be smooth, coated or granule-surfaced. The asphalt used in the manufacture of the modified sheets is, as the name suggests, modified with a polymer—APP (atactic polypropylene) or SBS (styrene butadiene styrene). Sheets produced with a greater amount of polymer tend to be the better performers.

Historically APP was heat/torch-applied and SBS was hot asphalt- or cold-applied but in recent years this distinction has been blurred. Some self-adhering membranes are now on the market, as well. The advent of liquid-applied flashing systems has greatly improved detailing. Like its BUR cousin, modified bitumen requires a cant to transition membrane from one plane to another, requiring extra curb and roof edge heights; liquid flashing has minimized those requirements.

In addition to smooth and granule surfacing, modified cap sheets can now be procured with a reflective coating to meet various codes and standards. Caution: Ponding water can erode many of the acrylic coatings, leaving the base asphalt unprotected.

For designers, confusion comes from the fact that no two modified sheets are the same. They all differ to some extent (as opposed to the roof covers described previously, which are very similar in composition). Thus, in my opinion, specifications should be specific and list approved manufacturers and the approved products by name, not performance criteria.

PHOTO 6: The owner preferred a granule-surfaced modified bitumen roof system for durability against repeated foot traffic.

Modified bitumen and its many formulations have performed well, but in the past decade have lost marketshare because of cost of material and lack of skilled labor to install multiple plies.

WHAT IS THE BEST ROOF COVER?

The best roof cover is one that is selected with due diligence; has compatible system components; and is appropriate for the building, climate and contractor’s ability. There is no one roof cover for all conditions and when forced on a building for which it is not appropriate or installed by unqualified contractors or designed—or should I say not designed—by unqualified designers, failure occurs.

Additional information about low-slope roof covers can be found in The NRCA Roofing Manual: Membrane Roof Systems, as well as manufacturer websites.

PHOTOS: HUTCHINSON DESIGN GROUP LTD

MORE FROM HUTCH

“Roofs Are Systems”, January/February 2014, page 52

“Roof Decks”, March/April 2014, page 54

“Substrate Boards”, July/August 2014, page 52

“Vapor Retarders”, September/October 2014, page 52

“Insulation”, November/December 2014, page 50

“Wind-damaged Roof Systems”, January/ February 2015, page 60

“Cover Boards”, September/October 2015, page 60

Be the first to comment on "The Roof Cover: The Cap on the Roof System"