WATER ABSORPTION

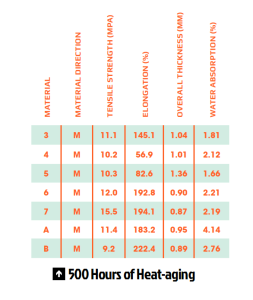

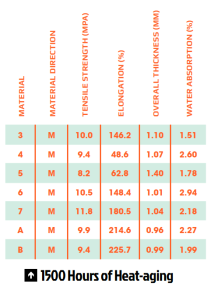

As shown in the tables 1 to 3, the water absorption was well below the +8/-2 percent level set in ASTM D4637/4637M. This indicated that the samples were resistant to water absorption.

The mechanical response of the samples under tensile loading was measured and displayed as force-displacement curves. They varied with test direction and exposure.

Samples were tested before and after exposure. The tensile strengths of the samples were 8.2 – 15.5 MPa MD. The majority were above the ASTM specification of 9.0 MPa. The tensile elongations at break of the field samples prior to heat-aging are 313 – 514 percent and 287 – 506 percent for MD and XD, which exceeded the ASTM specification of 300 percent for new material and 200 percent after heat-conditioning of new material. This shows that the material maintained its flexibility after 30 years in the field. Further heat-conditioning led to a reduced elongation in the membranes.

A decrease in elongation associated with an increase in tensile strength can indicate that a change in the mechanical properties of a material has taken place as a direct result of being exposed to the elements. Solar radiation, rain, temperature change or air pollution may affect a membrane. However, if the material degradation was quite severe, tensile strength and elongation value should decrease. As can be observed from the data, the values for most of the membranes decreased

after heat-conditioning of the 30-year-old field samples. It is possible that at this point, processing oils, for example, were being lost because of the heat-conditioning, leading to the changes in tensile properties.

LONG SERVICE LIFE

It is obvious from in situ performance and the data on membrane 30-years plus in age, as well as those of the heat-conditioning membrane, that 60- and 90-mil EPDM roof membranes will have service lives that greatly exceed those of their thinner cousins. Installing a roof with a long-term service life benefits not only the owners, building users and communities in which they are located, but also benefits the environment and in turn society and mankind.

In addition to membrane longevity, EPDM has excellent hail resistance and its darker color adds a safety factor against condensation below the roof membrane, a characteristic that has long affected reflective membranes. Furthermore, Tulsa, Okla.-based GreenTeam Inc. found that EPDM has the lowest global-warming potential, smog impacts and acid-rain impact of any of the major roof covers available today. The environmental consulting team determined this while completing EPDM’s life-cycle assessment using the Washington-based U.S. Environmental Protection Agency’s TRACI, or Tool for the Reduction and Assessment of Chemical and other Environmental Impacts. These facts and a history of long-term performance have resulted in a new 40-year roof warranty coverage being made available by manufacturers.

MORE STUDIES

“Procuring a roof system, which based on historical performance and design will last 30 years plus is what this district is all —achieving sustainability based on fact, not prediction. The district’s best environmental choice is a roof with an EPDM roof membrane.” —Don Stevenson, director of Building and Grounds, School District 65, Evanston, Ill.

PHOTOS: HUTCHINSON DESIGN GROUP LTD.

What are your thoughts on a light molecular weight fluid applied Liquid EPDM membrane system?