Insulation securement: Mechanical fasteners create 7 percent energy loss when used under the membrane. Heat transfers through the metal to the surface of the roof. Walk on a frost-covered roof where mechanical fasteners are below the membrane surface and the frost will be melted.

Coverboard type: Some are moisture-resistant while others actually attract moisture. Selecting the incorrect one can result in failure of the product.

The interior function of the space directly below the roof system should be considered in the design. City-center buildings often have mechanical spaces below the roof, which do not benefit from high insulation layers or reflective roof surfaces. In fact, both of these can be detrimental to the roof system’s long-term service life.

Roof cover: Only after all these previous considerations, the roof cover and surface come into play. Let’s consider single-ply membrane thicknesses: 45, 55, 60, 80 or 90 mil. A 45-mil membrane is not robust enough to typically perform for the long term. How the membrane is attached also is a consideration. Will it be mechanically fastened? This often is a poor choice because it pumps air into the roof system, causing it to flutter; allows for unabated air movement; and creates the potential for condensation below the membrane. Will it be ballasted? Fully adhered? The RhinoBond specialty attachment method is another option. Some attachment methods are temperature-restricted, as well.

Other Considerations

In addition to the roof-system components, the quality of their installation is also very important. Specifying multiple layers of insulation only to have the contractor install it with open gaps between boards and voids at the perimeter and penetrations will render even the best roof design energy inefficient.

Furthermore, designers need to consider the environment in which the roof will be placed, or the micro-climate effect. Placing a reflective roof in the shade of trees, higher buildings, mountains, etc., does nothing in regard to energy conservation.

The design team must also consider how the building’s systems work, as they too affect the building’s energy performance

HVAC systems: Are there ceilings, attics, plenums, or is the conditioned air ducted? Are the ducts adequately insulated? Uninsulated ducts can contribute heat and/or cooling temperature increases to the space and can affect interior comfort. Temperature variations below the roof deck can also affect the performance and longevity of the roof system.

Wall systems: How well are they insulated and integrated into the roof? Walls with cavities can allow stack-effect air movement to enter into roof systems, especially those that are not adhered in place. This can create condensation and mold.

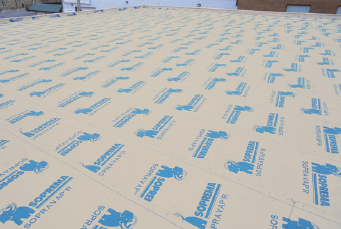

This high-performance roof system is composed of (1) a 45-mil EPDM vapor retarder on substrate board mechanically fastened to a steel roof deck and (2) two layers of 3-inch 25-psi, double-coated fiberglass-faced polyisocyanurate insulation set in bead-foam adhesive at 4 inches on center, weighted with five 5-gallon pails of adhesive per 4- by 4-foot board to ensure a positive bond into the bead foam until set. (3) All open joints, gaps and voids between the insulation and perimeter and penetrations have been sealed with spray-foam insulation. (4) One-half-inch modified gypsum coverboard

was set in bead-foam adhesive at 4 inches on center, weighted with five 5-gallon pails of adhesive per 4- by 4-foot board to ensure a positive bond into the bead foam until set. (5) The 90-mil EPDM was fully adhered to the coverboard. All lap seams were overlaid with self-adhering semi-cured EPDM cover strips set in splice adhesive, and all edges were sealed with lap sealant. ANSI-SPRI ES-1-designed roof-edge copings followed the roof system installation.

Windows: How much solar gain and heat loss will be contributed by them? Windows can have a large effect on the interior comfort of a building.

As one can quickly see, the interrelationship of roof components and then roof and building systems dictates the final outcome of the building envelope’s contribution to energy conservation. The roofing industry, through varying associations, is trying to educate codes and standards committees about the importance of seeing roofs as systems and urge them not to make decisions based on a single component. Most, if not all codes and standards decision-makers have little to no roof system knowledge and are reviewing proposals from individuals or associations with similar roofing ignorance. Best of all, these individuals and groups have absolutely no liability for the decisions they make. Thus, they are placing the liability on designers! That is a scary proposition when the design of a proper roof system on many an advanced building is beyond knowledge of most architects, engineers and roof consultants, not to mention contractors. We all learn best by our empirical experiences; let’s not learn through roof system failure and litigation.

In subsequent articles, I will explain various roof system components and review design considerations related to material and product selection, attachment options, service-life potential and appropriate use. I will offer personal opinions based on my in-the-field experiences.

Happy designing.

IMAGES: Hutchinson Design Group LLC

Be the first to comment on "Attention Roof System Designers: Numerous Roof Components Work Together to Affect a Building"